When it rains heavily and rivers turn a murky brown, you’re witnessing sedimentation in action. Those swirling particles of sand, silt, and clay are nature’s way of letting gravity do its thing. But sedimentation isn’t just about muddy rivers or the gradual buildup of dirt on your favorite hiking trail—it’s a process that’s vital in industries like water treatment, construction, and even the beverages we drink.

So, what exactly is sedimentation, and why should you care? Sedimentation is the process where particles suspended in a fluid (like water) settle to the bottom under the influence of gravity or other forces. Think of it as nature’s cleanup crew—particles separate out, leaving cleaner fluid behind. It’s simple but surprisingly sophisticated, with four distinct types that each have their unique characteristics and uses.

The Basics of Sedimentation

Before we get to the four types of sedimentation, let’s start with the basics. Understanding the fundamentals of sedimentation gives context to why it’s such an important process across various domains.

What Is Sedimentation?

At its core, sedimentation is the act of separating particles from a liquid by allowing them to settle at the bottom under gravity. This seemingly simple process has profound implications. For instance:

- It’s how rivers carve out landscapes over millennia.

- It’s the backbone of water purification systems.

- It’s even how your favorite craft beer is clarified (no one wants a cloudy pint unless it’s intentional!).

How Does Sedimentation Work?

Gravity is the hero of this story. When particles are suspended in a liquid, they’re in a constant state of motion. Over time, gravity pulls the denser particles downward. The speed of this settling depends on several factors:

- Particle Size and Density: Larger, denser particles settle faster than smaller ones.

- Viscosity of the Liquid: Thicker liquids slow down the settling process.

- External Forces: In engineered systems, stirring or centrifugal force can accelerate sedimentation.

This process happens in two primary contexts:

- Natural Sedimentation: Rivers, lakes, and oceans are prime examples. Over time, sediments form layers that tell us stories about Earth’s history.

- Industrial Sedimentation: Used in industries like wastewater treatment, mining, and even food production.

Applications of Sedimentation

Sedimentation isn’t just a natural wonder; it’s a practical tool. Some common applications include:

- Water Treatment: Removing solids from water to make it safe for drinking or industrial use.

- Mining: Extracting valuable minerals from ore by separating particles based on density.

- Construction: Settling concrete mixtures to ensure proper layer formation.

- Environmental Studies: Monitoring sedimentation rates to assess erosion or pollution levels.

Why Is Sedimentation Important?

Sedimentation touches nearly every aspect of life, from keeping ecosystems healthy to ensuring your tap water is crystal clear. It’s essential for maintaining infrastructure (like dams and reservoirs), managing pollution, and supporting sustainable practices in industries.

For example, did you know that excessive sedimentation in rivers can damage aquatic habitats? Or that poorly managed sedimentation in reservoirs can reduce their capacity, leading to flooding risks? These examples highlight why studying sedimentation is more than just an academic pursuit—it’s a necessity for preserving our planet and our resources.

What Are the 4 Types of Sedimentation?

Sedimentation isn’t a one-size-fits-all process. Depending on the characteristics of the particles, the fluid, and the conditions, sedimentation can occur in one of four distinct ways. Let’s explore each type in detail.

1. Discrete Sedimentation

What Is Discrete Sedimentation?

Imagine dropping a handful of sand into a glass of water. The grains of sand sink individually, unaffected by one another. That’s discrete sedimentation—a process where individual particles settle without clumping together or interacting.

This type is common when:

- The concentration of particles is low.

- Particles are small and uniformly distributed.

- Conditions allow particles to settle independently.

Examples of Discrete Sedimentation

- Sediment settling in calm rivers or lakes.

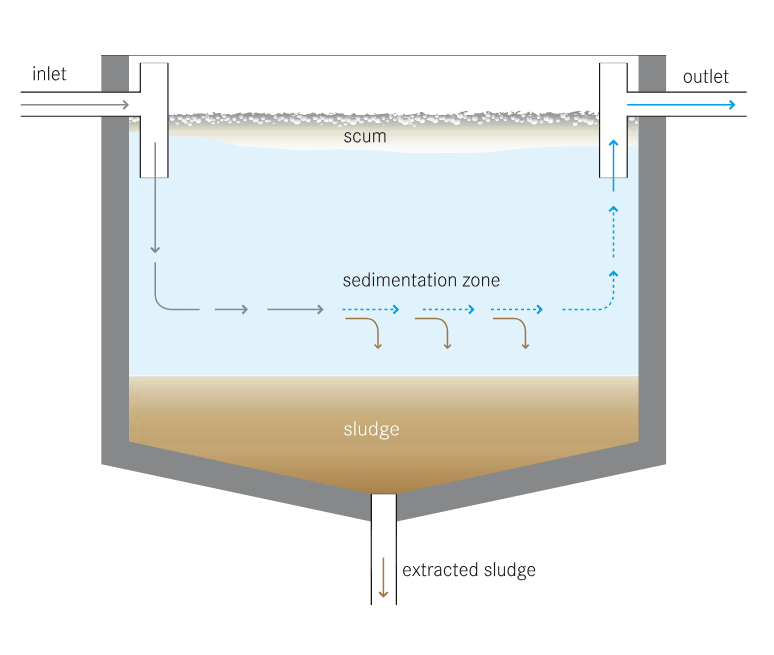

- Primary sedimentation tanks in water treatment plants, where particles like grit and sand are removed before further processing.

Why Does It Matter? Discrete sedimentation is the simplest form of settling and often serves as the first step in water and wastewater treatment systems. Engineers design clarifiers and sedimentation tanks to optimize this process, ensuring that particles settle efficiently.

2. Flocculent Sedimentation

What Is Flocculent Sedimentation?

Now picture a muddy pond. Over time, the particles in the water start sticking together, forming larger clumps called flocs. These flocs are heavier and settle faster than individual particles. This is flocculent sedimentation, a process driven by particle interactions.

How Does It Work? Flocculent sedimentation often occurs when chemicals (like coagulants or flocculants) are added to the water. These chemicals encourage particles to stick together, making them easier to separate.

Applications

- Wastewater Treatment: Removing fine particles that wouldn’t settle individually.

- Food and Beverage Industry: Clarifying liquids like juices and wines.

- Natural Settings: Coastal areas where organic matter aggregates due to biological activity.

Fun Fact

Flocculent sedimentation is why clear lakes stay, well, clear! Organic particles and algae naturally flocculate, keeping the water clean and healthy.

3. Hindered (Zone) Sedimentation

What Is Hindered Sedimentation?

Imagine a thick slurry of mud. When the concentration of particles is very high, they no longer settle independently. Instead, the particles create a dense zone and settle as a collective mass. This is hindered or zone sedimentation.

Key Features

- Particles interact strongly, forming a network.

- A clear boundary often forms between the settling mass and the clearer liquid above.

Industrial Applications

- Mining: Managing thick slurries of ore and tailings.

- Water Treatment: Secondary clarifiers where sludge is formed.

- Civil Engineering: Sediment consolidation in dredging projects.

Why Is It Important? Hindered sedimentation is vital for processes that deal with high particle loads. For example, in mining operations, it ensures that valuable minerals are separated efficiently from waste.

4. Compression Sedimentation

What Is Compression Sedimentation?

Let’s go even further into the mud analogy. At the very bottom of that thick slurry, particles are so densely packed that they start compressing under their own weight. This is compression sedimentation—a process where the bottom layers of particles are compacted as more sediment accumulates above.

Characteristics

- Occurs under high particle concentrations.

- Compression increases as weight and pressure build up.

Applications

- Sludge Management: In wastewater treatment plants, compression sedimentation thickens sludge for easier disposal or treatment.

- Geological Processes: Formation of sedimentary rock layers over millions of years.

- Land Reclamation: Compressing dredged sediments to create stable ground for construction.

A Cool Case Study The formation of sedimentary rocks like shale and sandstone is a natural example of compression sedimentation. Over millennia, layers of sediment are compacted under immense pressure, eventually forming solid rock. That’s sedimentation in action on a geological timescale!

Comparing the 4 Types of Sedimentation

| Type | Key Features | Common Applications | Example |

|---|---|---|---|

| Discrete Sedimentation | Particles settle independently | Water treatment, rivers | Sand in a glass of water |

| Flocculent Sedimentation | Particles clump together (flocs) | Wastewater, food processing | Clarifying juice or wine |

| Hindered Sedimentation | Particles settle as a dense zone | Mining, thickener tanks | Muddy slurry settling in a tank |

| Compression Sedimentation | Layers compress under high pressure | Sludge treatment, geological layers | Sedimentary rock formation |

Each type of sedimentation plays a unique role in nature and industry. Whether it’s clarifying water for a city or understanding how ancient rock layers formed, sedimentation is an essential process that keeps our world functioning smoothly.

Factors Influencing Sedimentation Types

Sedimentation might sound straightforward—particles settle under gravity, end of story. But the reality is more nuanced. The speed, efficiency, and type of sedimentation depend on various factors. Let’s break down the main influences.

Particle Characteristics

The size, shape, and density of particles play a huge role in sedimentation.

- Size: Larger particles, like sand, settle faster than tiny clay particles. This principle is described by Stokes’ Law, which predicts settling velocity based on particle diameter.

- Shape: Spherical particles settle more efficiently, while irregularly shaped ones can tumble, slowing their descent.

- Density: Denser materials like metal ores sink rapidly compared to lighter organic matter.

Fun Analogy

Imagine a race between a bowling ball and a feather in a swimming pool. The bowling ball (denser and compact) wins every time, while the feather drifts lazily down. Sedimentation works in a similar way.

Fluid Properties

The characteristics of the liquid in which sedimentation occurs also have a significant impact.

- Viscosity: Thicker fluids (like syrup) resist particle movement, slowing down sedimentation.

- Density: The closer the fluid’s density is to that of the particles, the slower they’ll settle. That’s why oil and water separate faster than oil and honey.

- Turbulence: In a calm fluid, particles settle uniformly. In turbulent conditions, sedimentation slows as particles are stirred up.

Example

Ever noticed how muddy water in a calm pond clears faster than in a flowing stream? That’s viscosity and turbulence at work.

Concentration of Particles

- Low Concentrations: Particles settle independently, as in discrete sedimentation.

- High Concentrations: Particles interact and may settle as a mass, leading to hindered or compression sedimentation.

Quick Fact

The denser the sediment load, the more likely it is to shift from discrete to hindered sedimentation. This transition is critical in industries like mining, where managing dense slurries efficiently is a top priority.

External Forces

In engineered systems, additional forces can alter sedimentation rates:

- Gravity: The primary driver in natural sedimentation.

- Centrifugal Force: Used in industrial centrifuges to accelerate sedimentation.

- Mechanical Inputs: Agitators can break up flocs or improve particle interaction for more efficient settling.

Industrial Insight

Centrifugal sedimentation is a game-changer in industries like pharmaceuticals, where separating fine particles quickly is essential.

5. Natural Sedimentation vs. Industrial Sedimentation

Natural Sedimentation

Nature has been perfecting sedimentation for millions of years. In rivers, lakes, and oceans, sedimentation shapes ecosystems and landforms.

- Erosion and Deposition: Soil and rocks are eroded by water and wind, transported, and eventually deposited as sediment.

- Layer Formation: Over time, these sediments form stratified layers that tell Earth’s history. Think of the Grand Canyon, a masterpiece of natural sedimentation.

Industrial Sedimentation

Humans have borrowed nature’s idea of sedimentation and supercharged it for practical use.

- Water Treatment Plants

- Sedimentation is the first step in clarifying water, removing heavy particles before filtration.

- Chemical additives enhance flocculent sedimentation for finer particles.

- Mining

- Separating valuable minerals from waste involves hindered and compression sedimentation techniques.

- Thickening tanks are designed to settle dense slurry mixtures.

- Food and Beverage

- Clarification processes in wine and juice production rely heavily on flocculent sedimentation.

Interesting Stat

Industrial sedimentation tanks can process thousands of liters of water every hour, removing up to 99% of suspended solids.

A Quick Recap of Key Factors

| Factor | Influence on Sedimentation | Example |

|---|---|---|

| Particle Size & Density | Larger, denser particles settle faster | Sand vs. clay in water |

| Fluid Viscosity & Density | Thicker, denser fluids slow sedimentation | Honey vs. water |

| Turbulence | Reduces efficiency, disrupts settling | Streams vs. ponds |

| Particle Concentration | High concentrations lead to hindered sedimentation | Muddy slurry |

| External Forces | Accelerate or enhance settling | Centrifuges in industrial use |

Understanding these factors helps scientists and engineers control sedimentation processes for cleaner water, better construction materials, and more efficient resource extraction.

Challenges and Innovations in Sedimentation Processes

Sedimentation may seem like a naturally occurring process, but managing it efficiently—especially in industrial and environmental settings—comes with its fair share of challenges. Fortunately, modern innovations are helping to address these issues while improving efficiency and sustainability.

Challenges in Sedimentation

- Environmental Issues

- Pollution: Sediments in polluted rivers or lakes can contain harmful substances like heavy metals and chemicals. When these sediments settle, they can contaminate ecosystems and water supplies.

- Erosion and Siltation: Human activities like deforestation and agriculture can accelerate erosion, leading to excessive sedimentation in rivers and reservoirs. This not only disrupts aquatic habitats but also reduces reservoir capacity, increasing the risk of flooding.

- Efficiency in Industrial Processes

- Fine Particles: Extremely small particles, such as those in wastewater or mining operations, are slow to settle and often require additional treatment like coagulation or advanced filtration.

- High Costs: Adding chemicals like coagulants or building large sedimentation tanks can be expensive, especially for developing countries or small-scale operations.

- Climate Change

- Shifts in weather patterns affect natural sedimentation rates. For example, increased rainfall can lead to more sediment being transported into waterways, overwhelming existing infrastructure.

- Space Constraints

- In urban and industrial areas, finding space for large-scale sedimentation tanks or ponds can be challenging, forcing engineers to design more compact solutions.

Innovations in Sedimentation

- Advanced Flocculants

- Modern flocculants are more efficient at encouraging particle aggregation. Eco-friendly flocculants, derived from natural materials like plant-based polymers, are gaining popularity for their reduced environmental impact.

- High-Rate Sedimentation Tanks

- New designs, such as lamella clarifiers, increase settling efficiency by using inclined plates or tubes to reduce the distance particles need to travel. These systems are compact and highly effective for urban installations.

- Centrifugal Sedimentation

- Centrifuges use rotational force to speed up sedimentation. They’re particularly useful in industries like pharmaceuticals and food processing, where precision and speed are crucial.

- AI and Automation

- Smart sensors and AI systems are revolutionizing sedimentation monitoring. These tools can:

- Optimize chemical dosing in real time.

- Predict sedimentation rates based on incoming particle loads.

- Reduce waste by ensuring only the necessary amount of chemicals are used.

- Smart sensors and AI systems are revolutionizing sedimentation monitoring. These tools can:

Case Study Singapore’s water treatment facilities employ automated sedimentation monitoring systems to process millions of liters of water daily, ensuring optimal performance and sustainability.

Future Trends in Sedimentation

The future of sedimentation is focused on sustainability and innovation:

- Zero-Waste Technologies: Innovations aim to reuse sediments, such as turning them into building materials or fertilizers.

- Integration with Renewable Energy: Using solar-powered pumps and centrifuges to reduce the carbon footprint of sedimentation processes.

- Improved Modelling Tools: AI-powered simulations are being used to design better sedimentation systems, saving time and resources during construction.

Addressing the Challenges: A Balancing Act

While sedimentation is one of the most efficient ways to separate solids from liquids, balancing cost, efficiency, and environmental impact requires creativity and advanced technology. By embracing these innovations, industries can continue to improve sedimentation processes, ensuring they remain effective, affordable, and sustainable.